| Availability: | |

|---|---|

| Quantity: | |

The Underground Mobile Garbage Compression Station is a modern sanitation facility that integrates the functions of garbage collection, compression and storage in underground spaces. Through the "underground operation + ground decoration renovation" model, it achieves efficient, reduced and environmentally friendly garbage disposal, and is an important sanitation equipment for addressing the shortage of urban land resources and improving the quality of living environment.

![]() Product Advantage

Product Advantage

Volume reduction is the core function of a Underground Mobile Garbage Compression Station and the foundation of all its advantages. By applying high pressure to the trash using a hydraulic cylinder or mechanical ram, loose trash can be compressed to 1/3-1/5 of its original volume, directly improving efficiency.

Loose trash is prone to odor diffusion, leachate leakage, and scattered trash. Compactors, through their "compression and sealing" design, eliminate secondary pollution at the source.

By reducing volume and increasing efficiency, compressors indirectly reduce costs across the entire waste disposal chain, offering significant long-term cost-effectiveness.

Trash compactors come in a variety of types (horizontal, vertical, mobile, and fixed), allowing for flexible deployment based on diverse application needs and offering exceptional adaptability.

Traditional manual handling of loose trash can be prone to contact with sharp objects and hazardous contaminants, while compactors enhance operational safety through automated operation.

![]() Technical Parameters

Technical Parameters

Model | ZYM-6 | ZYM-9 | ZYM-12 | ZYM-15 | ZYM-18 |

Volume (m ³) | 6 | 9 | 12 | 15 | 18 |

Tank Dimensions (L*W*H)(mm) | 3980*2210*2200 | 4770*2210*2200 | 5080*2260*2250 | 5560*2300*2300 | 6150*2480*2410 |

Power(kw) | 11 | 11 | 11 | 15 | 15 |

| Foundation measurement design Additional controls e.g. emergency stops Custom filling hopper Drainage system 2-phase discharge door opening mechanism Top hinged discharge door Ozone generator / cooler device (odor control) Bin lift (integrated / stationary) Lid opening system (hydraulic / electronic) Auto start system | ||||

Optional | Garbage Bins: 240L*4 / 660L*2 (Garbage bins can be used for sorting or storing garbage temporarily when the tank is transferred.) Pit Flushing: high-pressure large volume water flow flushing, 6 nozzles for one-time automatic flushing; 500L sewage collection tank; automatic sewage discharge by sewage pump. (This technology is protected by independent intellectual property rights.) Remote Monitoring | ||||

![]() Product Effects

Product Effects

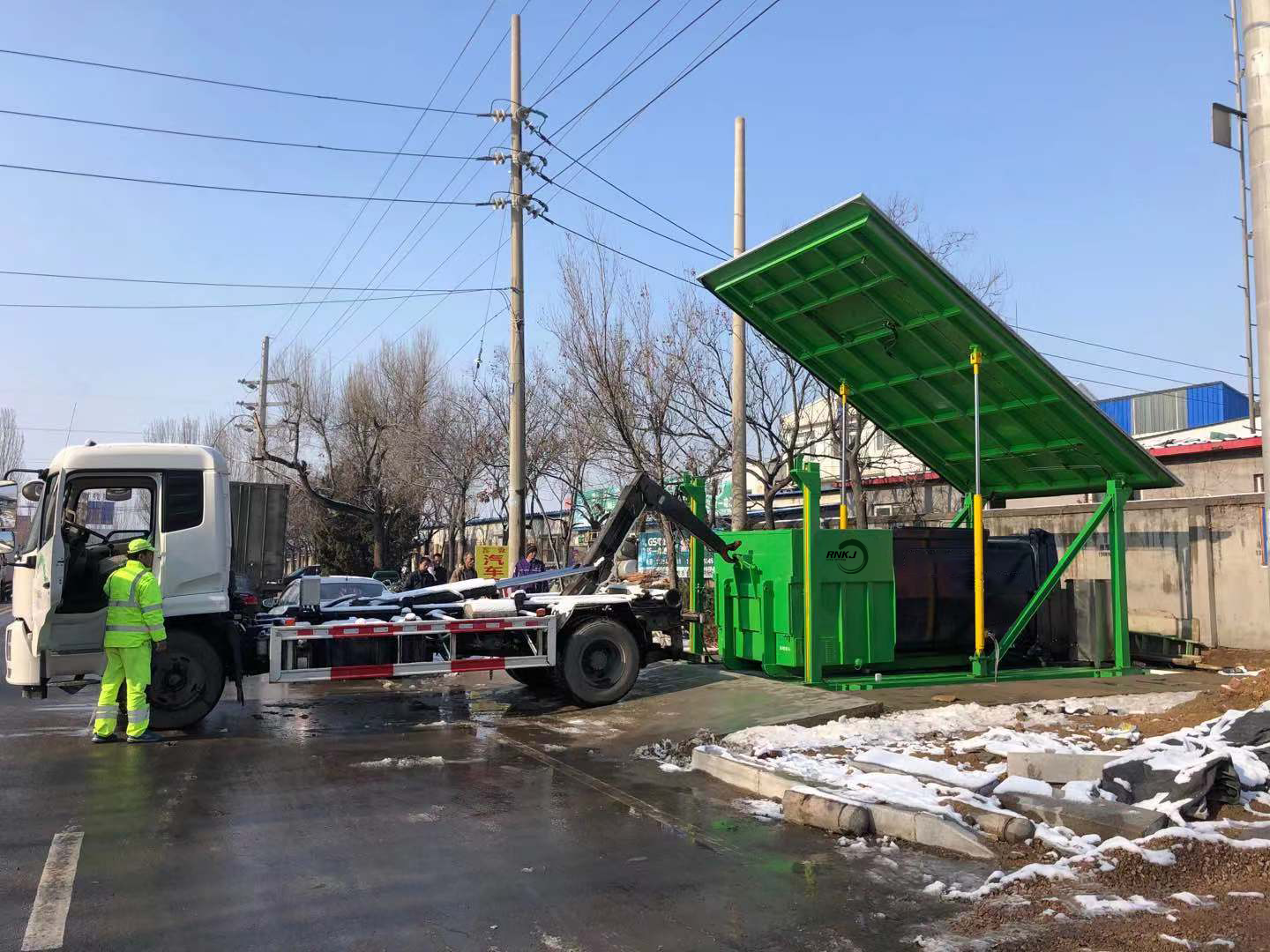

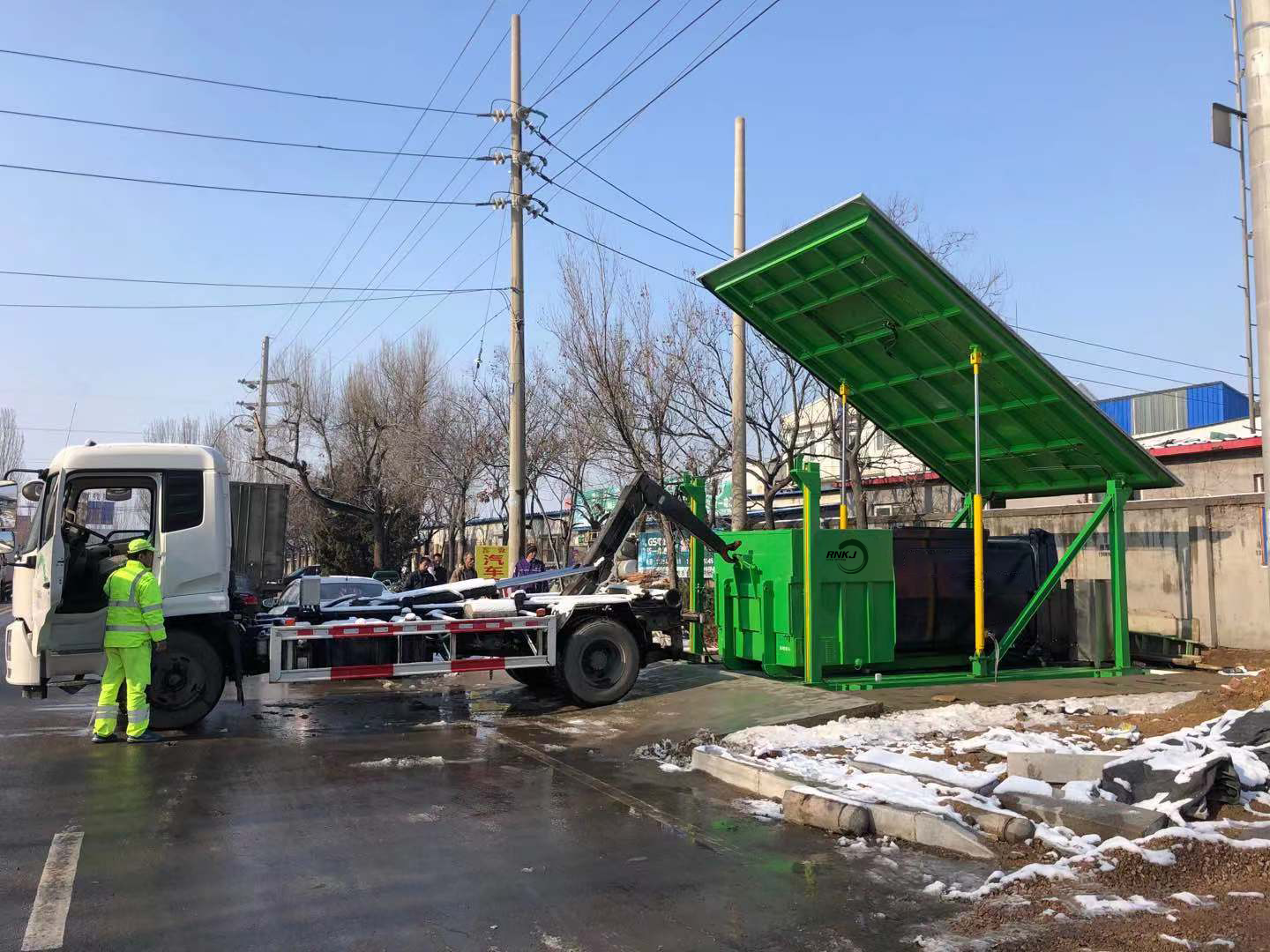

Lifting mode

Landing mode

![]() Product Application Scenarios & Functions

Product Application Scenarios & Functions

1. Urban Residential Areas

Applicable Scenarios: High-density residential complexes, older residential neighborhoods, and high-end residential properties.

Function: Addresses the pain points of "dispersed garbage collection points, frequent waste pickup, and unpleasant odors disrupting residents’ daily lives". It replaces traditional open-air garbage collection spots, significantly enhancing the overall cleanliness, hygiene, and living comfort of residential areas.

Applicable Scenarios: Commercial complexes, office clusters, hospitals, schools, and scenic spots—specifically areas with large foot traffic, high garbage generation volumes, and concentrated waste output.

Function: Daily garbage output in commercial areas can range from 5 to 20 tons. By leveraging efficient compression at underground stations, the number of waste collection vehicles is reduced, preventing frequent entry and exit of these vehicles from disrupting commercial operations and public order. In scenic spots, it preserves the integrity of the landscape and avoids damage to the natural environment caused by above-ground garbage stations.

Applicable Scenarios: Railway stations, subway stations, airport terminals, and urban core business districts—areas characterized by high land value and heavy passenger flow.

Function: Garbage generation at transportation hubs is both concentrated and time-sensitive (e.g., packaging waste discarded by passengers). Underground stations enable "on-the-spot collection and immediate compression", preventing waste accumulation from impairing the passenger experience. In core business districts, the solution achieves "zero above-ground garbage accumulation", effectively enhancing the city’s image and upgrading the overall urban living environment.

Applicable Scenarios: Narrow urban streets and densely built urban villages—locations where traditional above-ground waste stations are unable to be constructed due to space constraints.

Function: During the renovation of old urban areas, underground stations can be built using small corner spaces along streets (with an above-ground footprint equivalent to just one parking space). This addresses the long-standing challenges of "difficult waste collection" and "dirty, cluttered surroundings", providing strong support for improving living environments in the process of urban renewal.

![]() Operation Procedure

Operation Procedure

Before operation: Put on safety helmets, masks and other protective equipment; Check if the underground ventilation meets standards, there are no obstructions, and the lighting and communication are normal; Test the equipment's power (oil, battery), the compaction system (the press head is undamaged), and the safety devices (the emergency stop is effective) to ensure there are no faults.

During operation: Start the equipment at idle speed for 5-10 minutes, test the movement of the press head; Feed the material at the rated capacity, do not throw super-hard foreign objects; Compact in two stages: first, pre-compact at low pressure to remove air, then raise to the rated pressure and maintain for 1-2 minutes, monitor the pressure and the status of the press head.

After operation: Shut down the equipment and disconnect the power supply, clean the residual debris on the press head; Check if there is any leakage or wear of the equipment; Record the operation volume and equipment status, turn off the ventilation and lighting, and confirm there are no safety hazards before leaving.

![]() Custom Drop

Custom Drop

According to customer needs, we can choose a variety of feeding port modes such as garbage sorting and dumping port, bucket tipping device, large garbage opening device, etc.,

![]() Custom Floor Materials

Custom Floor Materials

The surface material can be arranged according to your surroundings, hiding the location of the compression station, ensuring smooth roads and achieving beautiful result.

![]() Our Advantages

Our Advantages

The system is equipped with automatic fire fighting, deodorization, ventilation and automatic clean facilities. Spray effecitvely reduces odor and disinfects, whose time and frenquency can be set up. High pressure water gun can rinse the surface of the tank and floor.

![]() Our Services

Our Services

Pre-sales & after-sales service

Pre-sales services:24-hour online service to provide you with convenient online remote service. With professional technical research and development personnel to provide you with personalized customized services, according to your needs for feasibility analysis, confirm the specifications parameters, as a technical assistant, in a timely manner for you to do a good job in the production of products to follow up, reliable quality testing and the necessary certificates to provide.

After-sales service:Online product installation tutorials, professional technical teacher online service, necessary door-to-door installation, core components warranty, the use of the process of Q&A, regular tracking of the use of equipment and so on.

You will receive our full range of personalized customized services, including to site design, packaging, equipment matching, customized procedures, etc,

When you purchase equipment from RNKJ. May wish you to start from a small transaction, experience the products and services from us.

![]() FAQ

FAQ

1. Who are we?

We are a professional manufacture, we have our own R&D team and sales team, we provide one-stop service.

2. How can we guarantee the quality?

Always have pre-production samples before mass production; Always have final inspection before shipment;

3. What can you buy from us?

Trash compactor,Underground garbage compactor,Underground collection system,Hook lift bin,Skip bin,Sweeper,sScrubber.

4. What services can we provide?

Customized bins are accepted.Someone will answer your questions at any time, 24 hours online.We will provide pre-sales and after-sales service

5.What shall we do if we do not have drawings?

Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order.

We are a professional manufacturer of sanitation machinery, providing customers with ex-factory prices and on-demand customization services. You can contact us via WhatsApp or email.

The Underground Mobile Garbage Compression Station is a modern sanitation facility that integrates the functions of garbage collection, compression and storage in underground spaces. Through the "underground operation + ground decoration renovation" model, it achieves efficient, reduced and environmentally friendly garbage disposal, and is an important sanitation equipment for addressing the shortage of urban land resources and improving the quality of living environment.

![]() Product Advantage

Product Advantage

Volume reduction is the core function of a Underground Mobile Garbage Compression Station and the foundation of all its advantages. By applying high pressure to the trash using a hydraulic cylinder or mechanical ram, loose trash can be compressed to 1/3-1/5 of its original volume, directly improving efficiency.

Loose trash is prone to odor diffusion, leachate leakage, and scattered trash. Compactors, through their "compression and sealing" design, eliminate secondary pollution at the source.

By reducing volume and increasing efficiency, compressors indirectly reduce costs across the entire waste disposal chain, offering significant long-term cost-effectiveness.

Trash compactors come in a variety of types (horizontal, vertical, mobile, and fixed), allowing for flexible deployment based on diverse application needs and offering exceptional adaptability.

Traditional manual handling of loose trash can be prone to contact with sharp objects and hazardous contaminants, while compactors enhance operational safety through automated operation.

![]() Technical Parameters

Technical Parameters

Model | ZYM-6 | ZYM-9 | ZYM-12 | ZYM-15 | ZYM-18 |

Volume (m ³) | 6 | 9 | 12 | 15 | 18 |

Tank Dimensions (L*W*H)(mm) | 3980*2210*2200 | 4770*2210*2200 | 5080*2260*2250 | 5560*2300*2300 | 6150*2480*2410 |

Power(kw) | 11 | 11 | 11 | 15 | 15 |

| Foundation measurement design Additional controls e.g. emergency stops Custom filling hopper Drainage system 2-phase discharge door opening mechanism Top hinged discharge door Ozone generator / cooler device (odor control) Bin lift (integrated / stationary) Lid opening system (hydraulic / electronic) Auto start system | ||||

Optional | Garbage Bins: 240L*4 / 660L*2 (Garbage bins can be used for sorting or storing garbage temporarily when the tank is transferred.) Pit Flushing: high-pressure large volume water flow flushing, 6 nozzles for one-time automatic flushing; 500L sewage collection tank; automatic sewage discharge by sewage pump. (This technology is protected by independent intellectual property rights.) Remote Monitoring | ||||

![]() Product Effects

Product Effects

Lifting mode

Landing mode

![]() Product Application Scenarios & Functions

Product Application Scenarios & Functions

1. Urban Residential Areas

Applicable Scenarios: High-density residential complexes, older residential neighborhoods, and high-end residential properties.

Function: Addresses the pain points of "dispersed garbage collection points, frequent waste pickup, and unpleasant odors disrupting residents’ daily lives". It replaces traditional open-air garbage collection spots, significantly enhancing the overall cleanliness, hygiene, and living comfort of residential areas.

Applicable Scenarios: Commercial complexes, office clusters, hospitals, schools, and scenic spots—specifically areas with large foot traffic, high garbage generation volumes, and concentrated waste output.

Function: Daily garbage output in commercial areas can range from 5 to 20 tons. By leveraging efficient compression at underground stations, the number of waste collection vehicles is reduced, preventing frequent entry and exit of these vehicles from disrupting commercial operations and public order. In scenic spots, it preserves the integrity of the landscape and avoids damage to the natural environment caused by above-ground garbage stations.

Applicable Scenarios: Railway stations, subway stations, airport terminals, and urban core business districts—areas characterized by high land value and heavy passenger flow.

Function: Garbage generation at transportation hubs is both concentrated and time-sensitive (e.g., packaging waste discarded by passengers). Underground stations enable "on-the-spot collection and immediate compression", preventing waste accumulation from impairing the passenger experience. In core business districts, the solution achieves "zero above-ground garbage accumulation", effectively enhancing the city’s image and upgrading the overall urban living environment.

Applicable Scenarios: Narrow urban streets and densely built urban villages—locations where traditional above-ground waste stations are unable to be constructed due to space constraints.

Function: During the renovation of old urban areas, underground stations can be built using small corner spaces along streets (with an above-ground footprint equivalent to just one parking space). This addresses the long-standing challenges of "difficult waste collection" and "dirty, cluttered surroundings", providing strong support for improving living environments in the process of urban renewal.

![]() Operation Procedure

Operation Procedure

Before operation: Put on safety helmets, masks and other protective equipment; Check if the underground ventilation meets standards, there are no obstructions, and the lighting and communication are normal; Test the equipment's power (oil, battery), the compaction system (the press head is undamaged), and the safety devices (the emergency stop is effective) to ensure there are no faults.

During operation: Start the equipment at idle speed for 5-10 minutes, test the movement of the press head; Feed the material at the rated capacity, do not throw super-hard foreign objects; Compact in two stages: first, pre-compact at low pressure to remove air, then raise to the rated pressure and maintain for 1-2 minutes, monitor the pressure and the status of the press head.

After operation: Shut down the equipment and disconnect the power supply, clean the residual debris on the press head; Check if there is any leakage or wear of the equipment; Record the operation volume and equipment status, turn off the ventilation and lighting, and confirm there are no safety hazards before leaving.

![]() Custom Drop

Custom Drop

According to customer needs, we can choose a variety of feeding port modes such as garbage sorting and dumping port, bucket tipping device, large garbage opening device, etc.,

![]() Custom Floor Materials

Custom Floor Materials

The surface material can be arranged according to your surroundings, hiding the location of the compression station, ensuring smooth roads and achieving beautiful result.

![]() Our Advantages

Our Advantages

The system is equipped with automatic fire fighting, deodorization, ventilation and automatic clean facilities. Spray effecitvely reduces odor and disinfects, whose time and frenquency can be set up. High pressure water gun can rinse the surface of the tank and floor.

![]() Our Services

Our Services

Pre-sales & after-sales service

Pre-sales services:24-hour online service to provide you with convenient online remote service. With professional technical research and development personnel to provide you with personalized customized services, according to your needs for feasibility analysis, confirm the specifications parameters, as a technical assistant, in a timely manner for you to do a good job in the production of products to follow up, reliable quality testing and the necessary certificates to provide.

After-sales service:Online product installation tutorials, professional technical teacher online service, necessary door-to-door installation, core components warranty, the use of the process of Q&A, regular tracking of the use of equipment and so on.

You will receive our full range of personalized customized services, including to site design, packaging, equipment matching, customized procedures, etc,

When you purchase equipment from RNKJ. May wish you to start from a small transaction, experience the products and services from us.

![]() FAQ

FAQ

1. Who are we?

We are a professional manufacture, we have our own R&D team and sales team, we provide one-stop service.

2. How can we guarantee the quality?

Always have pre-production samples before mass production; Always have final inspection before shipment;

3. What can you buy from us?

Trash compactor,Underground garbage compactor,Underground collection system,Hook lift bin,Skip bin,Sweeper,sScrubber.

4. What services can we provide?

Customized bins are accepted.Someone will answer your questions at any time, 24 hours online.We will provide pre-sales and after-sales service

5.What shall we do if we do not have drawings?

Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order.

We are a professional manufacturer of sanitation machinery, providing customers with ex-factory prices and on-demand customization services. You can contact us via WhatsApp or email.