Spiral Trash Compactor is a mechanical device that uses a high-strength spiral drill to rotate, squeeze and push loose domestic and industrial waste. Its main objective is to significantly reduce the volume of the waste before it is loaded into containers or landfills, thereby enhancing transportation efficiency, reducing transportation frequency, saving space and operational costs.

![]() Advantages of a Spiral Trash Compactor

Advantages of a Spiral Trash Compactor

High space utilization: The compression ratio is high, enabling the maximum utilization of space in transfer stations or transportation containers.

Comprehensive transportation cost is low: The number of transportation trips has been reduced by at least half, significantly saving on fuel, vehicle wear and tear, and labor costs.

Strong continuous operation capability: With high automation level, it can achieve continuous operations of "material input - compression - full load".

Environmental benefits are excellent: The filtrate squeezed out during the compression process can be collected and treated, and the enclosed operation reduces pollution.

![]() Core Component Of Spiral Trash Compactor

Core Component Of Spiral Trash Compactor

Spiral assembly:

Spiral shaft: A core shaft made of high-strength alloy steel, which bears torque and thrust.

Spiral blades: Strip-shaped blades that are welded or specially connected to the spiral shaft. They are the components that directly contact and push the garbage. Usually, they adopt variable pitch and variable diameter designs to optimize the compression effect; the surfaces will undergo wear-resistant hardening treatment to extend the lifespan.

Spiral head: The conical or specially-shaped head at the front end, used for breaking and introducing garbage.

Compression chamber and frame:

Main compression chamber: A sturdy box-shaped structure where the garbage is initially compressed. The inner walls are equipped with wear-resistant liners.

Frame: An integral frame made by welding thick steel plates and angle steel, serving as the installation foundation for all components, bearing huge working stress, and must have extremely high rigidity and strength.

Guide rail: The screw assembly slides smoothly back and forth on it.

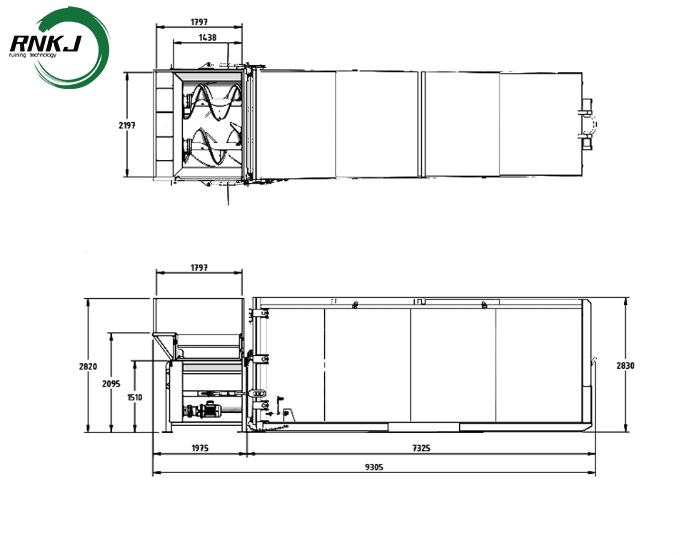

![]() Product Parameters

Product Parameters

Performance Parameters | |

Compression | Horizontal |

Waste bin volume (m³) | 6m³, 9m³,12m³ ,15m³ ,18m³,Custom sizes |

Hook centre height (mm) | 1570 |

Density of compressed rubbish block(kg/m³) | 750kg/m³ |

Compression cycle time (s) | 45s |

Max. lifting force of tipping bucket | 1t,1.5t,2t,2.5t,2.5t |

Tipping bucket volume (m³) | 1.5m³,2.5m³,3.2m³,4.1m³,4.1m³ |

Rated power of motor(kW) | 5KW,5.5KW, 7.5KW |

Machine weight (kg) | 4800kg,5500kg,6080kg,6580kg, |

Power supply | Local working voltage |

Operation mode | Automatic + manual |

Size | 6m³: 4180 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 9m³: 5080 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 12m³ :4180 * 5280 * 2600 (mm); Tipping bucket falling height 2410mm. |

![]() Working principle

Working principle

Garbage Disposal: The garbage truck dumps the loose garbage into the feed hopper or the front end of the compression chamber of the equipment.

Spiral Compression: The spiral drill bit starts to operate, rotating at high speed while moving horizontally towards the container. The spiral blades excavate the garbage heap like a "drill bit" and force it into the rear of the container.

Continuous Compaction: As the spiral continues to advance and rotate, the garbage is compacted layer by layer within the container, resulting in a significant increase in density.

Container Full: When the container is completely and tightly filled, the spiral retracts, the container door closes, and it is transported to the processing site by the grab-arm vehicle.

![]() Scope of Application and Limitations

Scope of Application and Limitations

Applicable: Kitchen waste, municipal sludge, screen residue, paper, foam plastic, etc. - loose or highly humid materials.

Limitation: For high-hardness large-sized materials, pre-treatment is required; otherwise, they may get stuck in the machine or cause wear on the screw.

![]() Features Of Spiral Trash Compactor

Features Of Spiral Trash Compactor

Multifunctional integration: Completes the three functions of conveying, dehydration, and compaction simultaneously, with an efficient process

Continuous operation: Can operate 24 hours without interruption, with stable processing efficiency

Dryness adjustable: Controls the dryness of the discharged material by adjusting the blocking device, suitable for different processing requirements

Energy-saving and environmentally friendly: Low energy consumption (compared to hydraulic type), no risk of hydraulic oil leakage, more environmentally friendly

Adaptable: Can handle various forms of garbage, including viscous materials, fibrous waste, and lumps

Compact structure: Small in floor space, flexible installation, suitable for limited space locations

Easy maintenance: The entire machine mostly uses stainless steel materials, corrosion-resistant, and easy to clean

![]() How efficient is the Spiral Trash Compactor?

How efficient is the Spiral Trash Compactor?

The Spiral Trash Compactor, as the core equipment for garbage compaction and processing, has core advantages in aspects such as process adaptability, operational efficiency, operating cost, and environmental friendliness. Compared with traditional equipment like hydraulic compaction machines and heavy gravity compaction machines, it has unique technical and application advantages in garbage reduction processing. Moreover, its structural design also meets the actual needs of various garbage treatment scenarios.

The core efficiency of the Spiral Trash Compactor lies in its superior effect of compacting and dehydrating the crushed materials. The crushing process makes the garbage particles uniform, preventing large chunks from blocking the compression process, and the utilization rate of the spiral compaction is higher.

Continuous operation capability: The crushing module and the screw compaction module are synchronously driven in the same axis, both having a purely mechanical structure without a hydraulic system. There is no waiting time for the system. The equipment can operate continuously for 24 hours, and the effective operation rate of the equipment can still reach over 90%. Only regular cleaning of the tangled objects on the crushing blades, grinding the blades, and cleaning the screen mesh is required.

Full-process connection efficiency: No separate crushing machines or material conveying belts are required. Once garbage is fed into the hopper, it undergoes crushing and compaction, and the finished products are directly discharged from the outlet. A single piece of equipment can complete three processes, reducing the floor area by more than 50%, eliminating the time and labor required for material transportation and equipment connection.

Maintenance efficiency: Maintenance only requires attention to three types of easily damaged parts: grinding blades, spiral blades, and screen meshes. The modular design makes it convenient to replace the accessories and reduces maintenance costs.

Manual efficiency: The entire process is automated, requiring no manual operation. Only regular inspections and simple maintenance by staff are needed.

We are an established equipment manufacturer equipped with state-of-the-art production facilities, including CNC laser cutting machines, CNC bending machines and machining centers. These ensure our products’ superior quality and exquisite finish.

We accommodate custom design requirements based on drawings, backed by a robust technical team and skilled welding professionals. We look forward to cooperating with you.

Spiral Trash Compactor is a mechanical device that uses a high-strength spiral drill to rotate, squeeze and push loose domestic and industrial waste. Its main objective is to significantly reduce the volume of the waste before it is loaded into containers or landfills, thereby enhancing transportation efficiency, reducing transportation frequency, saving space and operational costs.

![]() Advantages of a Spiral Trash Compactor

Advantages of a Spiral Trash Compactor

High space utilization: The compression ratio is high, enabling the maximum utilization of space in transfer stations or transportation containers.

Comprehensive transportation cost is low: The number of transportation trips has been reduced by at least half, significantly saving on fuel, vehicle wear and tear, and labor costs.

Strong continuous operation capability: With high automation level, it can achieve continuous operations of "material input - compression - full load".

Environmental benefits are excellent: The filtrate squeezed out during the compression process can be collected and treated, and the enclosed operation reduces pollution.

![]() Core Component Of Spiral Trash Compactor

Core Component Of Spiral Trash Compactor

Spiral assembly:

Spiral shaft: A core shaft made of high-strength alloy steel, which bears torque and thrust.

Spiral blades: Strip-shaped blades that are welded or specially connected to the spiral shaft. They are the components that directly contact and push the garbage. Usually, they adopt variable pitch and variable diameter designs to optimize the compression effect; the surfaces will undergo wear-resistant hardening treatment to extend the lifespan.

Spiral head: The conical or specially-shaped head at the front end, used for breaking and introducing garbage.

Compression chamber and frame:

Main compression chamber: A sturdy box-shaped structure where the garbage is initially compressed. The inner walls are equipped with wear-resistant liners.

Frame: An integral frame made by welding thick steel plates and angle steel, serving as the installation foundation for all components, bearing huge working stress, and must have extremely high rigidity and strength.

Guide rail: The screw assembly slides smoothly back and forth on it.

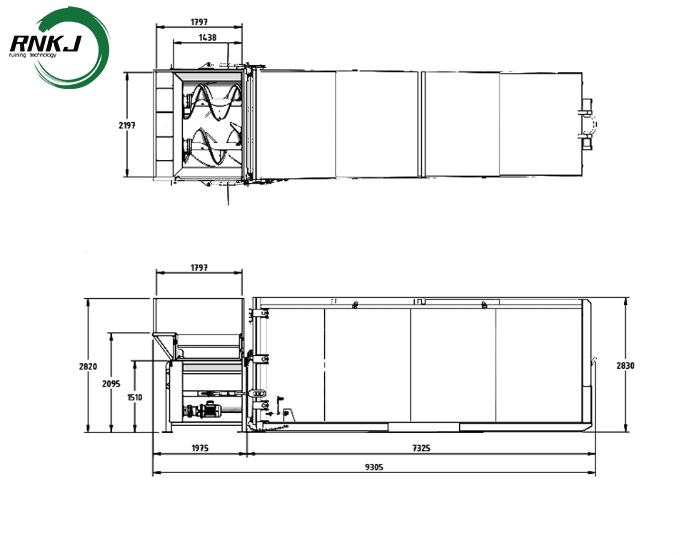

![]() Product Parameters

Product Parameters

Performance Parameters | |

Compression | Horizontal |

Waste bin volume (m³) | 6m³, 9m³,12m³ ,15m³ ,18m³,Custom sizes |

Hook centre height (mm) | 1570 |

Density of compressed rubbish block(kg/m³) | 750kg/m³ |

Compression cycle time (s) | 45s |

Max. lifting force of tipping bucket | 1t,1.5t,2t,2.5t,2.5t |

Tipping bucket volume (m³) | 1.5m³,2.5m³,3.2m³,4.1m³,4.1m³ |

Rated power of motor(kW) | 5KW,5.5KW, 7.5KW |

Machine weight (kg) | 4800kg,5500kg,6080kg,6580kg, |

Power supply | Local working voltage |

Operation mode | Automatic + manual |

Size | 6m³: 4180 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 9m³: 5080 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 12m³ :4180 * 5280 * 2600 (mm); Tipping bucket falling height 2410mm. |

![]() Working principle

Working principle

Garbage Disposal: The garbage truck dumps the loose garbage into the feed hopper or the front end of the compression chamber of the equipment.

Spiral Compression: The spiral drill bit starts to operate, rotating at high speed while moving horizontally towards the container. The spiral blades excavate the garbage heap like a "drill bit" and force it into the rear of the container.

Continuous Compaction: As the spiral continues to advance and rotate, the garbage is compacted layer by layer within the container, resulting in a significant increase in density.

Container Full: When the container is completely and tightly filled, the spiral retracts, the container door closes, and it is transported to the processing site by the grab-arm vehicle.

![]() Scope of Application and Limitations

Scope of Application and Limitations

Applicable: Kitchen waste, municipal sludge, screen residue, paper, foam plastic, etc. - loose or highly humid materials.

Limitation: For high-hardness large-sized materials, pre-treatment is required; otherwise, they may get stuck in the machine or cause wear on the screw.

![]() Features Of Spiral Trash Compactor

Features Of Spiral Trash Compactor

Multifunctional integration: Completes the three functions of conveying, dehydration, and compaction simultaneously, with an efficient process

Continuous operation: Can operate 24 hours without interruption, with stable processing efficiency

Dryness adjustable: Controls the dryness of the discharged material by adjusting the blocking device, suitable for different processing requirements

Energy-saving and environmentally friendly: Low energy consumption (compared to hydraulic type), no risk of hydraulic oil leakage, more environmentally friendly

Adaptable: Can handle various forms of garbage, including viscous materials, fibrous waste, and lumps

Compact structure: Small in floor space, flexible installation, suitable for limited space locations

Easy maintenance: The entire machine mostly uses stainless steel materials, corrosion-resistant, and easy to clean

![]() How efficient is the Spiral Trash Compactor?

How efficient is the Spiral Trash Compactor?

The Spiral Trash Compactor, as the core equipment for garbage compaction and processing, has core advantages in aspects such as process adaptability, operational efficiency, operating cost, and environmental friendliness. Compared with traditional equipment like hydraulic compaction machines and heavy gravity compaction machines, it has unique technical and application advantages in garbage reduction processing. Moreover, its structural design also meets the actual needs of various garbage treatment scenarios.

The core efficiency of the Spiral Trash Compactor lies in its superior effect of compacting and dehydrating the crushed materials. The crushing process makes the garbage particles uniform, preventing large chunks from blocking the compression process, and the utilization rate of the spiral compaction is higher.

Continuous operation capability: The crushing module and the screw compaction module are synchronously driven in the same axis, both having a purely mechanical structure without a hydraulic system. There is no waiting time for the system. The equipment can operate continuously for 24 hours, and the effective operation rate of the equipment can still reach over 90%. Only regular cleaning of the tangled objects on the crushing blades, grinding the blades, and cleaning the screen mesh is required.

Full-process connection efficiency: No separate crushing machines or material conveying belts are required. Once garbage is fed into the hopper, it undergoes crushing and compaction, and the finished products are directly discharged from the outlet. A single piece of equipment can complete three processes, reducing the floor area by more than 50%, eliminating the time and labor required for material transportation and equipment connection.

Maintenance efficiency: Maintenance only requires attention to three types of easily damaged parts: grinding blades, spiral blades, and screen meshes. The modular design makes it convenient to replace the accessories and reduces maintenance costs.

Manual efficiency: The entire process is automated, requiring no manual operation. Only regular inspections and simple maintenance by staff are needed.

We are an established equipment manufacturer equipped with state-of-the-art production facilities, including CNC laser cutting machines, CNC bending machines and machining centers. These ensure our products’ superior quality and exquisite finish.

We accommodate custom design requirements based on drawings, backed by a robust technical team and skilled welding professionals. We look forward to cooperating with you.