Hydraulic Hopper Trash Compactor is a common type of waste disposal equipment, which is mainly used to compress loose waste to reduce its volume, making it easier for transportation and subsequent processing.

Hydraulic Hopper Trash Compactor is a medium-sized environmental sanitation equipment that integrates functions of garbage collection, storage and compression. It achieves unobstructed garbage disposal through a large opening hopper at the top, and combines with a hydraulic compression system to compress loose garbage into high-density blocks. It is mainly used for centralized processing of household garbage in communities, commercial streets, towns, etc., and is a key equipment connecting the front-end collection and the end-of-line transportation.

![]() Product Advantage

Product Advantage

No need for dedicated vehicles: Ordinary manual hand carts and electric three-wheeled cleaning vehicles can directly dump garbage into the hopper. There is no need to additionally configure garbage collection vehicles with flipping functions, thus reducing the initial investment.

Low requirements for operators: No complex training is needed. The sanitation workers can complete the compression process simply by operating the buttons.

Limited site requirements: No need for a specially hardened reversing ramp. Just a 10-15 square meter flat surface is sufficient for installation. It can be adapted to both old residential areas and alleys.

Odor control is excellent: After the garbage is poured in, it directly enters the sealed compression chamber. The hopper is equipped with an automatic closing anti-odor cover plate. Some high-end models also have a spray deodorization system, which can effectively reduce the spread of odors.

Anti-spread design: There is a 15-20 cm high barrier around the hopper. During the compression process, the garbage will not spill out, avoiding secondary pollution.

Low noise pollution: The noise during compression operations is generally between 60 and 70 decibels, which is 10 to 15 decibels lower than that of large compression stations. It will not cause any disturbance to the surrounding residents.

Low equipment procurement cost: 30% - 50% cheaper than horizontal and vertical compression stations with the same processing capacity. The price of a single unit is generally within the range of 50,000 - 150,000 yuan.

Low maintenance cost: The structure is relatively simple, and the only wear-prone parts are the hydraulic seals and the push head wear-resistant plates. The annual maintenance cost is only 2% to 3% of the total equipment price.

Transportation cost savings: The compression ratio can reach 3:1 - 5:1, which can reduce 60% - 80% of garbage transfer trips, significantly lowering fuel and labor costs.

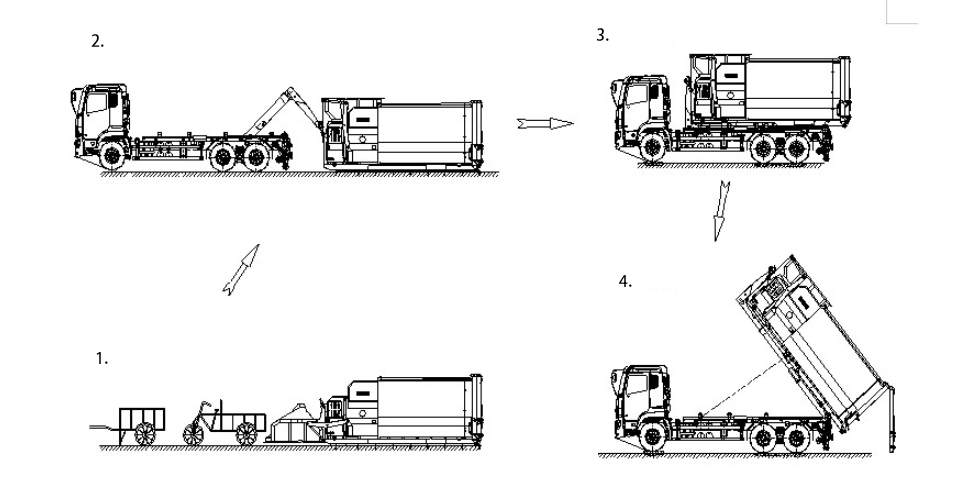

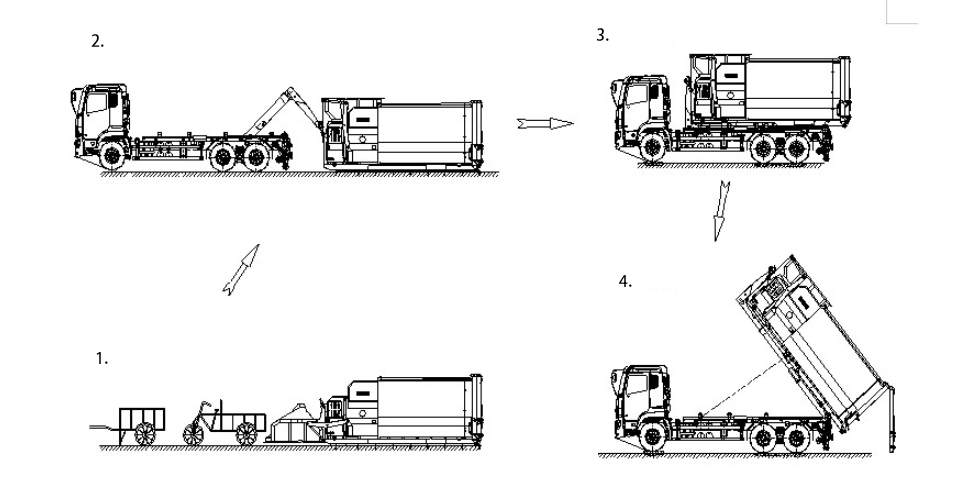

![]() Working Process

Working Process

Loading stage: Use hand carts or small transfer vehicles to directly pour the garbage into the hopper of the compression station.

Connection stage: When the storage box is fully loaded, the garbage transfer vehicle connects with the compression station. The hydraulic arm connects the storage box to the transfer vehicle.

Transportation stage: Fix the storage box on the transfer vehicle and transport it to the waste treatment site.

Discharging stage: After arriving at the treatment site, the storage box is lifted and tilted by the hydraulic system to complete the garbage discharge.

![]() Product Parameters

Product Parameters

Performance Parameters | |

Compression | Horizontal |

Waste bin volume (m³) | 6m³, 9m³,12m³ ,15m³ ,18m³,Custom sizes |

Hook centre height (mm) | 1570 |

Density of compressed rubbish block(kg/m³) | 750kg/m³ |

Compression cycle time (s) | 45s |

Max. lifting force of tipping bucket | 1t,1.5t,2t,2.5t,2.5t |

Tipping bucket volume (m³) | 1.5m³,2.5m³,3.2m³,4.1m³,4.1m³ |

Rated power of motor(kW) | 5KW, 5.5KW, 7.5KW |

Machine weight (kg) | 4800kg,5500kg, 6080kg,6580kg, |

Power supply | Local working voltage |

Operation mode | automatic + manual |

Size | 6m³: 4180 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 9m³: 5080 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 12m³ :4180 * 5280 * 2600 (mm); Tipping bucket falling height 2410mm. |

Support Customization

Intelligent SMART technology

![]() Structural Composition

Structural Composition

Loading unit

Large-volume open hopper: The opening can accommodate 1-2 cubic meters of loose garbage

Anti-spillage enclosure: The edges of the hopper are equipped with rubber or stainless steel enclosures

Automatic cover: Some high-end models come with a hydraulically-driven anti-smell cover that automatically closes when not in use

Compression unit

Compression chamber: Made of thick steel plates welded together, with wear-resistant liners inside

Hydraulic push head: Equipped with a hydraulic cylinder with a thrust of 10-20 tons, with a compression stroke of 1.5-2 meters

Hydraulic system: Composed of an electric motor, oil pump, hydraulic cylinder, and control valve group, with a working pressure of up to 16-25 MPa

Storage unit

Storage box: The volume is generally 3-8 cubic meters, capable of storing 10-20 tons of compressed garbage

Discharge mechanism: Through hydraulic lifting or sliding mechanisms, it can be connected and discharged with the garbage transfer vehicle

Sealing design: The box body uses rubber sealing strips to prevent the leakage of garbage leachate

Control unit

Operation panel: Equipped with buttons, indicator lights and a touch screen, supporting manual/automatic operation modes

Safety system: Equipped with infrared sensing, emergency stop, overload protection and other devices

Smart module: Some models support remote monitoring, fault diagnosis and data statistics functions

![]() Feature Of Hydraulic Hopper Trash Compactor

Feature Of Hydraulic Hopper Trash Compactor

Operational convenience: No need for dedicated garbage collection vehicles; manual hand carts can complete the loading

Cost controllability: Equipment procurement and maintenance costs are 30%-50% lower than those of large compression stations

Environmentally friendly: The enclosed compression structure reduces the spread of odors; some are equipped with deodorization systems

Versatility: Small in size, suitable for scenarios with limited space such as old residential areas and towns

Efficiency: High compression ratio, significantly reducing the number of garbage transfer vehicles

High compression ratio: Generally, the volume of garbage can be compressed to about 1/3 of its original size, effectively reducing the number of garbage transportation times and the space requirements for processing.

Good environmental performance: With a closed structure, it can effectively reduce the dirtiness, unpleasant odors, and mosquito and fly breeding problems that occur during garbage stacking, compression, and transportation, thereby reducing secondary pollution.

Diverse loading methods: It can meet the loading requirements of various garbage collection methods such as manual pallet trucks, three-wheel vehicles, and dump garbage trucks.

High automation level: Some bin-type garbage compression stations are equipped with intelligent sensing systems, which can achieve automatic classification of garbage, and can also automatically adjust the oil cylinder thrust according to the load situation of garbage compression, reducing labor input and improving work efficiency.

![]() Working Principle

Working Principle

After the garbage collection vehicle pours the garbage into the hopper, it drives the press head through the hydraulic system, and the press head moves along the track and passes through the hopper to exert pressure on the garbage inside the garbage bin, compressing the garbage into blocks. During the compression process, the wastewater in the garbage will be squeezed out and treated by a dedicated wastewater collection system. The volume of the compressed garbage can be significantly reduced. When the garbage bin is full, the transfer vehicle will transport the garbage bin away for subsequent processing, such as landfilling or incineration.

![]() Our Factory

Our Factory

Shandong RNKJ Environmental Technology Co., Ltd. is a high-tech enterprise that integrates the research and development, production, sales, service and environmental engineering construction of waste management equipment. With 25 years of marketing and practical innovation experience in the industry, it provides global customers with comprehensive solutions covering garbage collection, transportation and waste reduction treatment, as well as one-stop procurement services.

We are a professional manufacturer of sanitation machinery, providing customers with ex-factory prices and on-demand customization services. You can contact us via WhatsApp or email.

Hydraulic Hopper Trash Compactor is a common type of waste disposal equipment, which is mainly used to compress loose waste to reduce its volume, making it easier for transportation and subsequent processing.

Hydraulic Hopper Trash Compactor is a medium-sized environmental sanitation equipment that integrates functions of garbage collection, storage and compression. It achieves unobstructed garbage disposal through a large opening hopper at the top, and combines with a hydraulic compression system to compress loose garbage into high-density blocks. It is mainly used for centralized processing of household garbage in communities, commercial streets, towns, etc., and is a key equipment connecting the front-end collection and the end-of-line transportation.

![]() Product Advantage

Product Advantage

No need for dedicated vehicles: Ordinary manual hand carts and electric three-wheeled cleaning vehicles can directly dump garbage into the hopper. There is no need to additionally configure garbage collection vehicles with flipping functions, thus reducing the initial investment.

Low requirements for operators: No complex training is needed. The sanitation workers can complete the compression process simply by operating the buttons.

Limited site requirements: No need for a specially hardened reversing ramp. Just a 10-15 square meter flat surface is sufficient for installation. It can be adapted to both old residential areas and alleys.

Odor control is excellent: After the garbage is poured in, it directly enters the sealed compression chamber. The hopper is equipped with an automatic closing anti-odor cover plate. Some high-end models also have a spray deodorization system, which can effectively reduce the spread of odors.

Anti-spread design: There is a 15-20 cm high barrier around the hopper. During the compression process, the garbage will not spill out, avoiding secondary pollution.

Low noise pollution: The noise during compression operations is generally between 60 and 70 decibels, which is 10 to 15 decibels lower than that of large compression stations. It will not cause any disturbance to the surrounding residents.

Low equipment procurement cost: 30% - 50% cheaper than horizontal and vertical compression stations with the same processing capacity. The price of a single unit is generally within the range of 50,000 - 150,000 yuan.

Low maintenance cost: The structure is relatively simple, and the only wear-prone parts are the hydraulic seals and the push head wear-resistant plates. The annual maintenance cost is only 2% to 3% of the total equipment price.

Transportation cost savings: The compression ratio can reach 3:1 - 5:1, which can reduce 60% - 80% of garbage transfer trips, significantly lowering fuel and labor costs.

![]() Working Process

Working Process

Loading stage: Use hand carts or small transfer vehicles to directly pour the garbage into the hopper of the compression station.

Connection stage: When the storage box is fully loaded, the garbage transfer vehicle connects with the compression station. The hydraulic arm connects the storage box to the transfer vehicle.

Transportation stage: Fix the storage box on the transfer vehicle and transport it to the waste treatment site.

Discharging stage: After arriving at the treatment site, the storage box is lifted and tilted by the hydraulic system to complete the garbage discharge.

![]() Product Parameters

Product Parameters

Performance Parameters | |

Compression | Horizontal |

Waste bin volume (m³) | 6m³, 9m³,12m³ ,15m³ ,18m³,Custom sizes |

Hook centre height (mm) | 1570 |

Density of compressed rubbish block(kg/m³) | 750kg/m³ |

Compression cycle time (s) | 45s |

Max. lifting force of tipping bucket | 1t,1.5t,2t,2.5t,2.5t |

Tipping bucket volume (m³) | 1.5m³,2.5m³,3.2m³,4.1m³,4.1m³ |

Rated power of motor(kW) | 5KW, 5.5KW, 7.5KW |

Machine weight (kg) | 4800kg,5500kg, 6080kg,6580kg, |

Power supply | Local working voltage |

Operation mode | automatic + manual |

Size | 6m³: 4180 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 9m³: 5080 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 12m³ :4180 * 5280 * 2600 (mm); Tipping bucket falling height 2410mm. |

Support Customization

Intelligent SMART technology

![]() Structural Composition

Structural Composition

Loading unit

Large-volume open hopper: The opening can accommodate 1-2 cubic meters of loose garbage

Anti-spillage enclosure: The edges of the hopper are equipped with rubber or stainless steel enclosures

Automatic cover: Some high-end models come with a hydraulically-driven anti-smell cover that automatically closes when not in use

Compression unit

Compression chamber: Made of thick steel plates welded together, with wear-resistant liners inside

Hydraulic push head: Equipped with a hydraulic cylinder with a thrust of 10-20 tons, with a compression stroke of 1.5-2 meters

Hydraulic system: Composed of an electric motor, oil pump, hydraulic cylinder, and control valve group, with a working pressure of up to 16-25 MPa

Storage unit

Storage box: The volume is generally 3-8 cubic meters, capable of storing 10-20 tons of compressed garbage

Discharge mechanism: Through hydraulic lifting or sliding mechanisms, it can be connected and discharged with the garbage transfer vehicle

Sealing design: The box body uses rubber sealing strips to prevent the leakage of garbage leachate

Control unit

Operation panel: Equipped with buttons, indicator lights and a touch screen, supporting manual/automatic operation modes

Safety system: Equipped with infrared sensing, emergency stop, overload protection and other devices

Smart module: Some models support remote monitoring, fault diagnosis and data statistics functions

![]() Feature Of Hydraulic Hopper Trash Compactor

Feature Of Hydraulic Hopper Trash Compactor

Operational convenience: No need for dedicated garbage collection vehicles; manual hand carts can complete the loading

Cost controllability: Equipment procurement and maintenance costs are 30%-50% lower than those of large compression stations

Environmentally friendly: The enclosed compression structure reduces the spread of odors; some are equipped with deodorization systems

Versatility: Small in size, suitable for scenarios with limited space such as old residential areas and towns

Efficiency: High compression ratio, significantly reducing the number of garbage transfer vehicles

High compression ratio: Generally, the volume of garbage can be compressed to about 1/3 of its original size, effectively reducing the number of garbage transportation times and the space requirements for processing.

Good environmental performance: With a closed structure, it can effectively reduce the dirtiness, unpleasant odors, and mosquito and fly breeding problems that occur during garbage stacking, compression, and transportation, thereby reducing secondary pollution.

Diverse loading methods: It can meet the loading requirements of various garbage collection methods such as manual pallet trucks, three-wheel vehicles, and dump garbage trucks.

High automation level: Some bin-type garbage compression stations are equipped with intelligent sensing systems, which can achieve automatic classification of garbage, and can also automatically adjust the oil cylinder thrust according to the load situation of garbage compression, reducing labor input and improving work efficiency.

![]() Working Principle

Working Principle

After the garbage collection vehicle pours the garbage into the hopper, it drives the press head through the hydraulic system, and the press head moves along the track and passes through the hopper to exert pressure on the garbage inside the garbage bin, compressing the garbage into blocks. During the compression process, the wastewater in the garbage will be squeezed out and treated by a dedicated wastewater collection system. The volume of the compressed garbage can be significantly reduced. When the garbage bin is full, the transfer vehicle will transport the garbage bin away for subsequent processing, such as landfilling or incineration.

![]() Our Factory

Our Factory

Shandong RNKJ Environmental Technology Co., Ltd. is a high-tech enterprise that integrates the research and development, production, sales, service and environmental engineering construction of waste management equipment. With 25 years of marketing and practical innovation experience in the industry, it provides global customers with comprehensive solutions covering garbage collection, transportation and waste reduction treatment, as well as one-stop procurement services.

We are a professional manufacturer of sanitation machinery, providing customers with ex-factory prices and on-demand customization services. You can contact us via WhatsApp or email.