Hopper Trash Compaction Station is an intelligent core equipment for urban sanitation that integrates garbage collection, efficient compression, and sealed transportation. It is specifically designed to address the high costs and significant pollution associated with the disposal of loose garbage, and it represents an efficient solution for waste management in cities and parks.

![]() Product Advantage

Product Advantage

Ultra-high reduction compression

The compression ratio reaches 3:1 to 5:1, and the compacted density of loose garbage can reach 0.8 tons per cubic meter. This significantly reduces the volume occupied by garbage and decreases the frequency of transportation.

Fully sealed anti-pollution

The hopper and the box body adopt a fully enclosed structure, preventing garbage from spilling, sewage from seeping out, and odors from spreading. It fully complies with environmental protection standards for sanitation.

Flexible and lightweight deployment

No need for complex construction; only 1 standard parking space is required for installation; compatible with boom trucks, supporting "one truck for multiple containers" circular transportation, and suitable for various scenarios of operation.

Intelligent and convenient operation

Equipped with PLC automatic control system, it can complete the entire process of "loading materials → compression → locking boxes" with just one click; it is also equipped with intelligent alarms for full-capacity and faults, reducing the threshold for manual operation.

![]() Core Function

Core Function

Dumping automatic loading: Supports direct unloading from tricycles and small collection vehicles, eliminating the need for manual handling, saving effort and being highly efficient;

Hydraulic strong compression: The hydraulic push head maintains a stable output pressure, ensuring uniform garbage compaction and preventing loose rebound;

Quick hook arm connection: Seamless compatibility with hook arm vehicles, the entire box transportation process is enclosed, eliminating the need for secondary loading and unloading, and reducing pollution risks.

![]() Product Parameters

Product Parameters

Performance Parameters | |

Compression | Horizontal |

Waste bin volume (m³) | 6m³, 9m³,12m³ ,15m³ ,18m³,Custom sizes |

Hook centre height (mm) | 1570 |

Density of compressed rubbish block(kg/m³) | 750kg/m³ |

Compression cycle time (s) | 45s |

Max. lifting force of tipping bucket | 1t,1.5t,2t,2.5t,2.5t |

Tipping bucket volume (m³) | 1.5m³,2.5m³,3.2m³,4.1m³,4.1m³ |

Rated power of motor(kW) | 5KW, 5.5KW, 7.5KW |

Machine weight (kg) | 4800kg,5500kg, 6080kg,6580kg, |

Power supply | Local working voltage |

Operation mode | automatic + manual |

Size | 6m³: 4180 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 9m³: 5080 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 12m³ :4180 * 5280 * 2600 (mm); Tipping bucket falling height 2410mm. |

Support Customization

Intelligent SMART technology

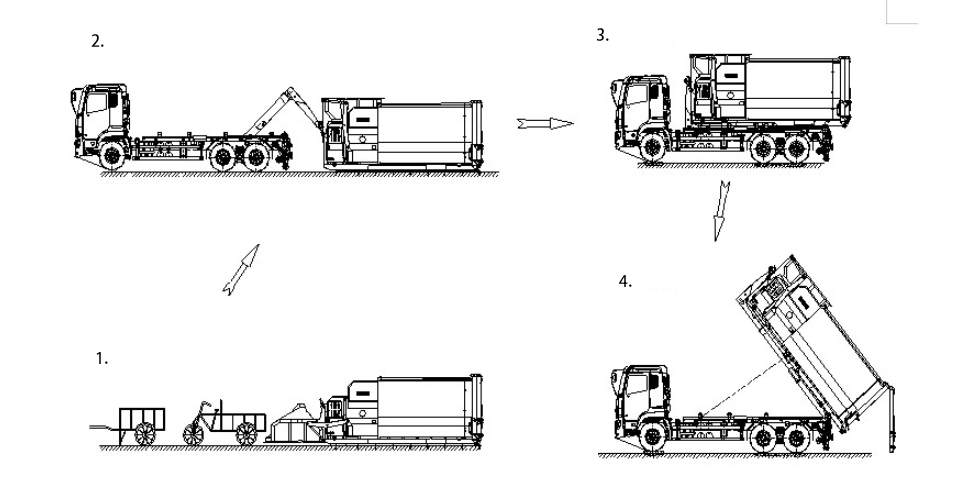

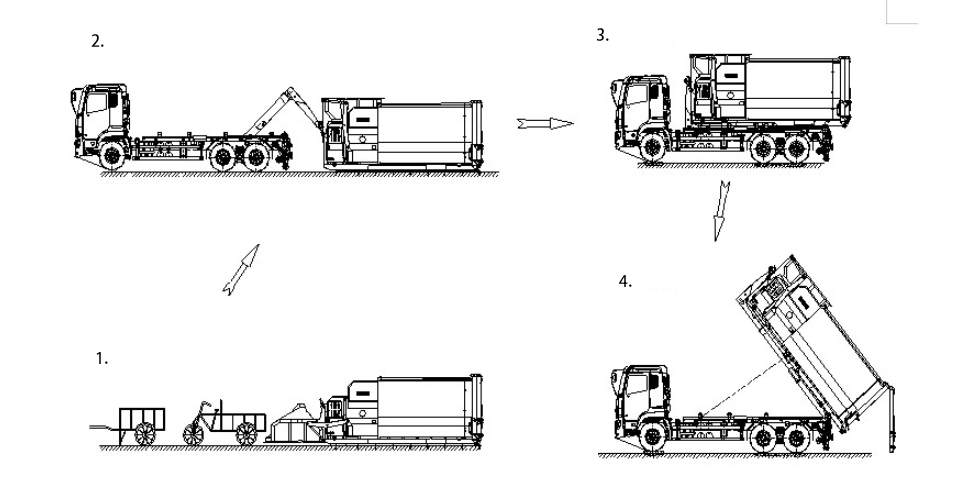

![]() Work Flow

Work Flow

Garbage Collection and Hopper Loading

Waste management workers either empty the garbage into the hopper installed at the top of the compressor, or directly discharge it by means of a skip loader truck or a manual cart.

The hopper is fitted with an auto-tipping mechanism, which conveys the waste into the compression chamber.

Compression and Storage

The hydraulic ram plate exerts high pressure to force the garbage into the storage bin. The compression cycle typically takes under 35 seconds. Certain equipment models incorporate dual-directional compression technology, thereby boosting the compression density even further.

Throughout the compression phase, leachate is diverted via the base-mounted drainage system, so as to avert environmental contamination.

Full-bin Handling and Transfer

Once the storage bin reaches its maximum load capacity, a built-in sensor sends a full-load alert, prompting the compression unit to shut down automatically and issue a warning.

A container handler truck connects to the storage bin and hauls it to the landfill site or waste incineration facility. The empty bin is then sent back to the transfer station through the dedicated container transfer platform, facilitating its repeated reuse.

![]() Applicable Scenarios

Applicable Scenarios

Municipal sanitation: Centralized treatment of domestic waste in communities, commercial streets, parks, etc.;

Industrial parks: Compression and transfer of industrial solid waste in industrial parks and logistics storage areas;

Public places: Garbage collection and transportation in densely populated areas such as schools, hospitals, scenic spots, etc.

![]() Product Value

Product Value

Cost Reduction: Reduce the number of collection trips, and lower transportation and labor costs;

Efficiency Enhancement: The daily processing capacity can reach 5 to 20 tons, improving the efficiency of garbage turnover;

Compliance: Meet the environmental protection construction requirements of "Urban-Rural Sanitation Integration" and "Zero Waste City".

![]() Product Feature

Product Feature

Strong compression and volume reduction effect: Compression ratio can reach 3:1 to 5:1, with high compaction density, significantly reducing the number of transportation trips.

Prevent secondary pollution: Fully sealed design, garbage, sewage, and odors will not spill out, and the transportation process remains enclosed.

Flexible and easy to deploy: No need for complex civil engineering, it can be used with just 1 parking space; compatible with boom trucks, it can be used to transport multiple boxes in a single vehicle in a cycle.

Intelligent and easy to operate: Equipped with PLC control system, it can automatically alarm, and the operation only requires pressing a button.

![]() Productive Capacity

Productive Capacity

Boasting over 20 years of industry experience, we have a professional R&D and design team. Coupled with advanced production equipment and automated production lines, we are well-equipped to fulfill large-scale order requirements.

International Certifications: The company has obtained ISO, CE, UL and other authoritative international quality and safety certifications.

Customized Services: We offer tailored solutions, including adjustments to product specifications, packaging design, and other aspects, to meet customers’ specific requirements.

We have a professional team and the strength of the factory to support customization. Including type, volume, height, color and other requirements, free custom logo.

![]() Production Line

Production Line

Liquid tight design.

Small footprint.

Compatible with collection vehicles from most manufacturers.Easy to connect with other existing loading equipment.

Strong, robust design and construction for a long service life.Equipped with hour counter and electric oil level sensor.

Complies with standards currently in force (CE, AFNOR and INRS).Numerous adaptions available and can be customized to your requirements.

We are a professional manufacturer of sanitation machinery, providing customers with ex-factory prices and on-demand customization services. You can contact us via WhatsApp or email.

Hopper Trash Compaction Station is an intelligent core equipment for urban sanitation that integrates garbage collection, efficient compression, and sealed transportation. It is specifically designed to address the high costs and significant pollution associated with the disposal of loose garbage, and it represents an efficient solution for waste management in cities and parks.

![]() Product Advantage

Product Advantage

Ultra-high reduction compression

The compression ratio reaches 3:1 to 5:1, and the compacted density of loose garbage can reach 0.8 tons per cubic meter. This significantly reduces the volume occupied by garbage and decreases the frequency of transportation.

Fully sealed anti-pollution

The hopper and the box body adopt a fully enclosed structure, preventing garbage from spilling, sewage from seeping out, and odors from spreading. It fully complies with environmental protection standards for sanitation.

Flexible and lightweight deployment

No need for complex construction; only 1 standard parking space is required for installation; compatible with boom trucks, supporting "one truck for multiple containers" circular transportation, and suitable for various scenarios of operation.

Intelligent and convenient operation

Equipped with PLC automatic control system, it can complete the entire process of "loading materials → compression → locking boxes" with just one click; it is also equipped with intelligent alarms for full-capacity and faults, reducing the threshold for manual operation.

![]() Core Function

Core Function

Dumping automatic loading: Supports direct unloading from tricycles and small collection vehicles, eliminating the need for manual handling, saving effort and being highly efficient;

Hydraulic strong compression: The hydraulic push head maintains a stable output pressure, ensuring uniform garbage compaction and preventing loose rebound;

Quick hook arm connection: Seamless compatibility with hook arm vehicles, the entire box transportation process is enclosed, eliminating the need for secondary loading and unloading, and reducing pollution risks.

![]() Product Parameters

Product Parameters

Performance Parameters | |

Compression | Horizontal |

Waste bin volume (m³) | 6m³, 9m³,12m³ ,15m³ ,18m³,Custom sizes |

Hook centre height (mm) | 1570 |

Density of compressed rubbish block(kg/m³) | 750kg/m³ |

Compression cycle time (s) | 45s |

Max. lifting force of tipping bucket | 1t,1.5t,2t,2.5t,2.5t |

Tipping bucket volume (m³) | 1.5m³,2.5m³,3.2m³,4.1m³,4.1m³ |

Rated power of motor(kW) | 5KW, 5.5KW, 7.5KW |

Machine weight (kg) | 4800kg,5500kg, 6080kg,6580kg, |

Power supply | Local working voltage |

Operation mode | automatic + manual |

Size | 6m³: 4180 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 9m³: 5080 * 2440 * 2600 (mm); Tipping bucket falling height 2410mm. 12m³ :4180 * 5280 * 2600 (mm); Tipping bucket falling height 2410mm. |

Support Customization

Intelligent SMART technology

![]() Work Flow

Work Flow

Garbage Collection and Hopper Loading

Waste management workers either empty the garbage into the hopper installed at the top of the compressor, or directly discharge it by means of a skip loader truck or a manual cart.

The hopper is fitted with an auto-tipping mechanism, which conveys the waste into the compression chamber.

Compression and Storage

The hydraulic ram plate exerts high pressure to force the garbage into the storage bin. The compression cycle typically takes under 35 seconds. Certain equipment models incorporate dual-directional compression technology, thereby boosting the compression density even further.

Throughout the compression phase, leachate is diverted via the base-mounted drainage system, so as to avert environmental contamination.

Full-bin Handling and Transfer

Once the storage bin reaches its maximum load capacity, a built-in sensor sends a full-load alert, prompting the compression unit to shut down automatically and issue a warning.

A container handler truck connects to the storage bin and hauls it to the landfill site or waste incineration facility. The empty bin is then sent back to the transfer station through the dedicated container transfer platform, facilitating its repeated reuse.

![]() Applicable Scenarios

Applicable Scenarios

Municipal sanitation: Centralized treatment of domestic waste in communities, commercial streets, parks, etc.;

Industrial parks: Compression and transfer of industrial solid waste in industrial parks and logistics storage areas;

Public places: Garbage collection and transportation in densely populated areas such as schools, hospitals, scenic spots, etc.

![]() Product Value

Product Value

Cost Reduction: Reduce the number of collection trips, and lower transportation and labor costs;

Efficiency Enhancement: The daily processing capacity can reach 5 to 20 tons, improving the efficiency of garbage turnover;

Compliance: Meet the environmental protection construction requirements of "Urban-Rural Sanitation Integration" and "Zero Waste City".

![]() Product Feature

Product Feature

Strong compression and volume reduction effect: Compression ratio can reach 3:1 to 5:1, with high compaction density, significantly reducing the number of transportation trips.

Prevent secondary pollution: Fully sealed design, garbage, sewage, and odors will not spill out, and the transportation process remains enclosed.

Flexible and easy to deploy: No need for complex civil engineering, it can be used with just 1 parking space; compatible with boom trucks, it can be used to transport multiple boxes in a single vehicle in a cycle.

Intelligent and easy to operate: Equipped with PLC control system, it can automatically alarm, and the operation only requires pressing a button.

![]() Productive Capacity

Productive Capacity

Boasting over 20 years of industry experience, we have a professional R&D and design team. Coupled with advanced production equipment and automated production lines, we are well-equipped to fulfill large-scale order requirements.

International Certifications: The company has obtained ISO, CE, UL and other authoritative international quality and safety certifications.

Customized Services: We offer tailored solutions, including adjustments to product specifications, packaging design, and other aspects, to meet customers’ specific requirements.

We have a professional team and the strength of the factory to support customization. Including type, volume, height, color and other requirements, free custom logo.

![]() Production Line

Production Line

Liquid tight design.

Small footprint.

Compatible with collection vehicles from most manufacturers.Easy to connect with other existing loading equipment.

Strong, robust design and construction for a long service life.Equipped with hour counter and electric oil level sensor.

Complies with standards currently in force (CE, AFNOR and INRS).Numerous adaptions available and can be customized to your requirements.

We are a professional manufacturer of sanitation machinery, providing customers with ex-factory prices and on-demand customization services. You can contact us via WhatsApp or email.